The leading cause of network failure is dirty connections. Almost all the time, the dirt is completely invisible to the naked eye.

Failure occurs when dirt gets on a connector ferrule end-face and blocks light. Preventing contamination is the reason all fiber connectors are protected with a dust cap or built-in shutter.

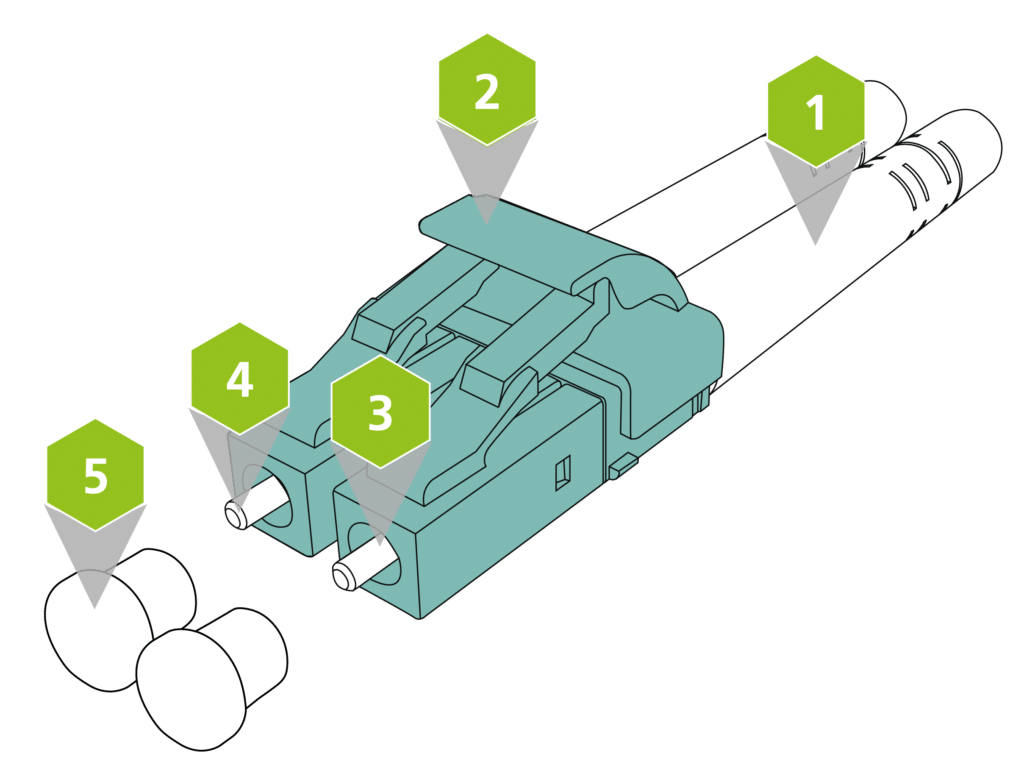

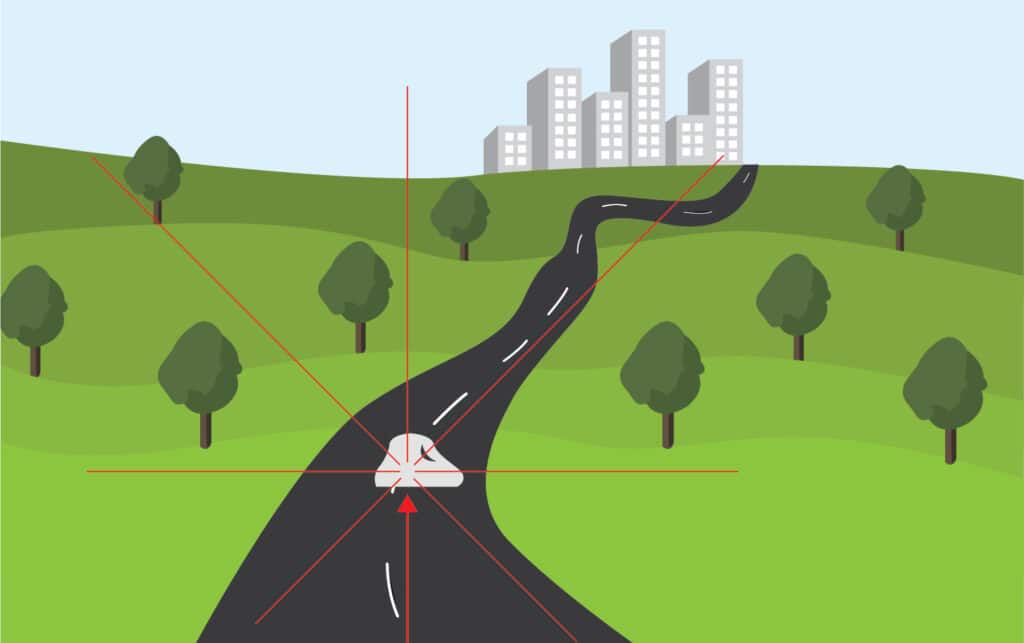

The diagram below shows an LC connector, one of the most widely used and recognized fiber connectors in the world:

- Connector Boot: Protects the optical fiber from bending and breaking.

- Connector Housing: Standardized so any LC can plug into a patch panel adaptor, active equipment or passive equipment with LC connections.

- Fiber Ferrule: Fiber Ferrule: Made from ceramic – holds the fiber in place and aligns fibers on connection

- Ferrule End Face: The tip of the connector. When two connectors are joined, both fibers come together completely to allow light to pass from one fiber to the other.

- Dustcap: Protects the fiber ferrule and end-face from sustaining damage, scratches or contamination.

When the dust cap is removed the ferrule end face can easily be contaminated by direct contact with skin oil, grease, salt, fingerprints, lint, uncured epoxy, grime or dust. Even just open air exposure may result in moisture and dust sticking to the end-face. When the dust caps are off your connectors are at risk of contamination.

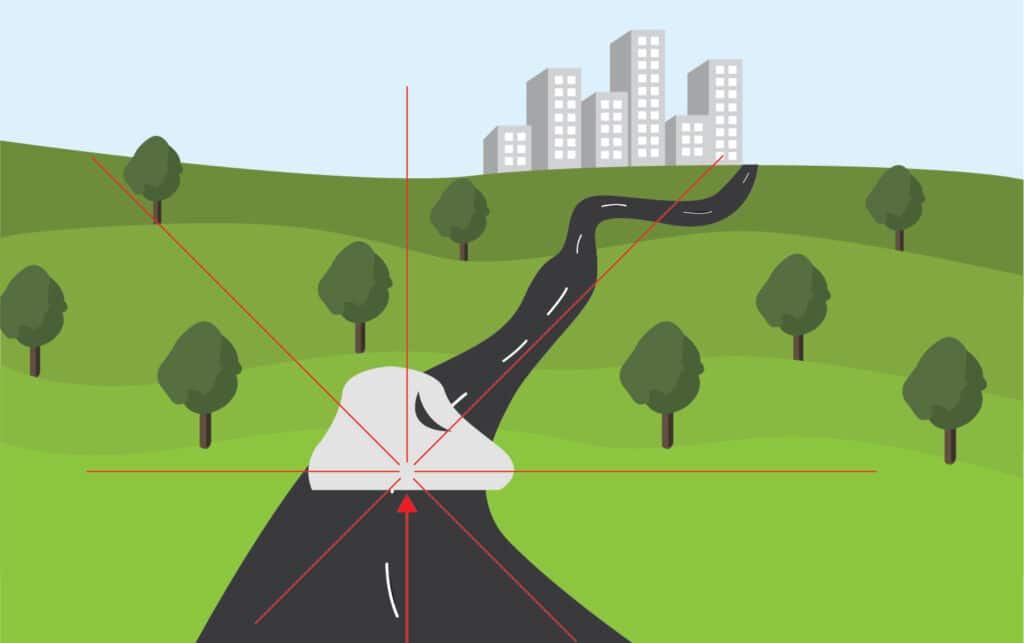

A 1 micron (one-millionth of a meter) dust particle is like a boulder in the middle of the optical road and will block up to half the light in a single mode fiber. A larger 9 micron speck, still invisible to the naked eye will block the whole road and no light will pass.

For high speed networks, even a 1 micron particle may cause the network to stop working.

To get the best connector performance and avoid failure due to dirt – inspect and clean, (if needed), EVERY connector before installation. Never connect an unchecked connector as this may cause dirt to become imbedded in the glass and cleaning may not be possible. Test lead connectors must also be inspected before EVERY connection.

Follow the steps below, and you will achieve the best performance from your single fiber connectors.

- Keep the dustcap on the connector until you are ready to connect. Only remove the dustcap prior to inspection and installation. If you plan to reuse the dustcap, keep it in a closed, clean container.

- Use a fiber inspection probe to inspect the end face of the connector to ensure there is no contamination. Never look at the end of the connector directly or with a simple optical instrument. The connection may be live with invisible high power light which can cause permanent eye damage. AFL offer a wide range of effective and safe connector inspection tools.

When inspecting, if contamination is found, continue to step 3, otherwise you may connect immediately.

- Clean the connector end face with one of the techniques shown below. Never allow cleaning alcohol (IPA) to evaporate from the ferrule as it can leave a residue that causes light to be reflected back into the fiber. Always follow wet cleaning with dry cleaning.

Cletop-SB

Cassette Cleaner

Fujikura One-Click® Cleaner

WFW and FA1 – FiberWipes™ and FiberAide

Micro Sticks

4. Check the end face of the connector by repeating Step 2. Once satisfied that the connector is free of contamination or defects, immediately install the connector into the adapter or active equipment. Never connect a dirty connector.

Follow this process every time you install or reinstall a fiber connector and eliminate the main reason for network failures. Follow this process every time you install or reinstall a fiber connector and eliminate the main reason for network failures.